Technical Specifications

Advantages :

• Applied for potable water pipeline system with hygienic and non-toxic features.

• High temperatures and high pressure resistant.

• Heat preservation and energy saving during the flow.

• Lighter and more smoother than the metal pipe.

• The reliable and convenient connecting pipes and fittings by homogeneity melt.

• Notice free at high flow rates.

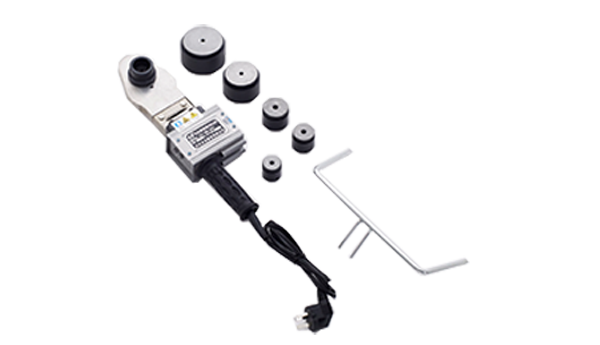

• Fusion technology's speed and ease of use.

• Significant time and labour savings.

• A long lifespan up to 25 years under normal conditions.

Applications:

RIFENG PP-R piping system can be used in following applications:• Cool and hot water distribution

• Pipes for connecting various types of low-temperature heating systems

• Pipes for solar energy system heating and cooling settings

• Cold water piping for air conditioners

Application areas:

• Potable water, hot and cold water, chemicals, irrigation

• Apartments, condominiums, and public housing

• Commercial shopping malls, as well as office buildings

• Chemical and food processing manufacturing plants

• Hospitals

• Schools, laboratories and chemical sewerage

• Hotels and resorts

Standards:

NSF /ANSI /CAN 61 – about Health Effects of Drinking water system components

DVGW W 544 – about PP-R pipe general mechanical requirement

DVGW W 270 – about Hygienic property of material

UBA KTW – about Hygienic property of material odor test

DIN 8077 – about Polypropylene pipe dimension

DIN 8078 – about Polypropylene pipe general quality requirement and testing

EN ISO15874 – about Plastic piping system for hot and cold water installation

Certificates:

NSF – from USA, refers to NSF /ANSI /CAN 61

DVGW – from German, refers to DVGW W 544,UBA KTW,DVGW W 270

AENOR – from Spain, refers to EN ISO 15874

CE – from Europe, refers to EN ISO 15874

ISO 9001:2015 – “Quality management system”

ISO 14001:2015 – “Environmental management system”

ISO 45001:2018 – “Occupational health and safety management system”

TYPE PPR Pipe PVC Pipe Copper pipe Roughness(μm) 0.4~1.0μm 1.5mm ≥2.0μm Melting point (℃) 145 No obvious melting point, softening point around 85℃ >900 Density (g/cm3) 0.89~0.91 1.42 8.96 Modulus of elasticity (MPa) 800 2900-3400 105-137 GPa Thermal conductivity (w/mK) 0.24 0.16 388~391 Coefficient of thermal expansion (mm/mK) 0.15 8*10-5 0.017 Property Test Method Unit Value Melt Flow Rate MFI 190/5 ISO 1133 g/10 dk. 0.5 MFI 230/2.16 ISO 1133 g/10 dk. 0.3 MFI 230/5 - g/10 dk. 1.5 Density at 23℃ ISO 1183 g/cm3 0.9 Tensile Stress at Yield ISO 527 Mpa 25 Elongation at Break ISO 527 % >50 Modulus of Elasticity, Tensile Test ISO 527 N/mm2 900 Impact Strength (Charpy) 23℃ ISO 179/1eU Kj/m2 No failure 0℃ ISO 179/1eU Kj/m2 No failure -10℃ ISO 179/1eU Kj/m2 No failure Notched Impact Strength (Charpy) 23℃ ISO 179/1eA Kj/m2 20 0℃ ISO 179/1eA Kj/m2 4 -10℃ ISO 179/1eA Kj/m2 3 Coefficient of Linear Thermal Expansion DIN 53 752 K-1 1.5×10-4 Thermal Conductivity at 20℃ DIN 52 612 W/mK 0.24 Specific Heat at 20℃ Adiabatic Calorimeter Kj/kg K 2 Standard Dimension Ratio (SDR)

RIFENG PPR pipe provide the following SDR-sizes:- SDR6

- SDR7.4

- SDR9

- SDR11

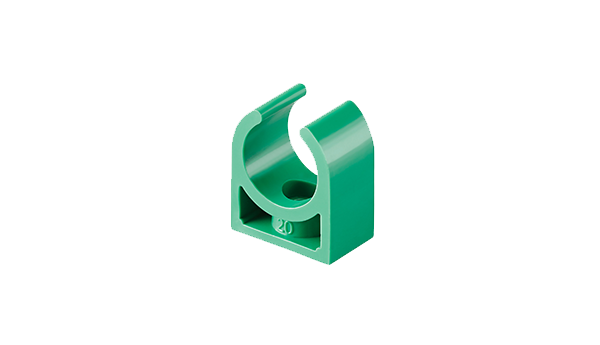

Dimensions: 20mm,25mm,32mm,40mm,50mm,63mm,75mm,90mm,110mm,160mm

Reliable homogeneous connections

Homogeneity melting provides reliable connection strength and sealing property between PP-R pipes and PP-R fittings.

Metal thread connectionRifeng also provides metal thread connection methods to achieve connection conversion between different scenarios.Rifeng PP-R fittings have an unique structure - swallow tailed structure on the metal insert, which can eliminate the risk of leakage from gaps caused by different thermal conductivity performances of brass and plastic.

Rifeng holds the exclusive patent to manufacture these fittings.

SWALLOW TAILED NOTCH 36 BITING POINTS BUTTON SAFETY RINGAvoid leakage risk caused by Anti-axial slip between metal Anti-over-twist when installingdifferent thermal expansions. insert and the plastic part. devices with threads.