Technical Specifications

• Entirely corrosion-resistant

• A strong barrier against oxygen and light

• Inherent stability and high bend flexibility

• Excellent hydrostatic stress performance

• Lightweight

• Less pressure loss is ensured by a smooth inner wall

• Up to 25 years of service life

• Both overlapping and butt welding are availableRIFENG Multilayer plumbing system can be used in the following applications: LPG vapor, natural gas, and natural gas liquids.

EN ISO 21003 - Multilayer piping systems for hot and cold water installations inside buildings

ASTM F1281 - Standard Specification For Crosslinked Polyethylene/Aluminum/Crosslinked Polyethylene (PEX-AL-PEX) Pressure Pipe.

BRL-K536 E - Plastics piping systems of PE-X/Al intended for the transport of cold and heated drinking water

DVGW W 534 (P) - Pipe Connectors and Pipe Joints in Drinking Water Installation

DVGW W 542 - COMPOUND PIPES IN THE DRINKING WATER INSTALLATION; REQUIREMENTS AND TESTING

DVGW W 270 - A method for the assessment of enhancement of microbial growth on non-metallic materials in contact with drinking water

UBA KTW - about Hygienic property of material odor test

UBA ELASTOM - Guideline for hygienic assessment of elastomers in contact with drinking water

AS 4176.2 & 3 - Multilayer piping for pressure applications - Multilayer piping systems for hot and cold water plumbing applications- PIPES & FITTINGS

XP P41-250 - Effect of materials on the quality of water intended for human consumption - Organic materials

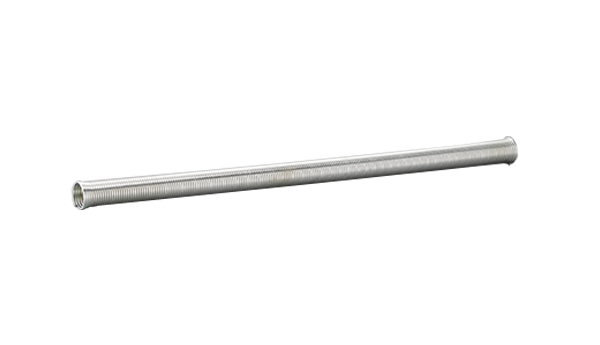

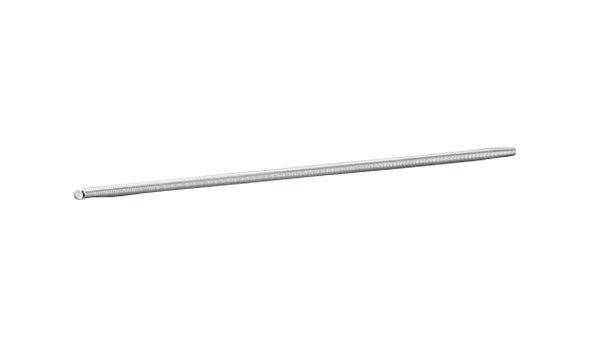

NSF /ANSI /CAN 61 - Health Effects of Drinking water system componentsTYPE Multilayer Pipe Overlapped welded A(PE-AL-PE) B1 (PEX-AL-PEX) B (PERT-AL-PERT) C (PE-AL-PE) Roughness(mm) 0.0007 0.0007 0.0007 0.0007 Melting point (℃) 135 - 127 127 Density (g/cm3) 0.941-0.959 0.926-0.959 0.926-0.940 0.941-0.959 Modulus of elasticity

(MPa)7200 7200 7200 7200 Thermal conductivity

(w/mK)0.45 0.45 0.45 0.45 Coefficient of thermal expansion (mm/mK) 0.025 0.025 0.025 0.025 Material Test item Requirement Polyethylene Density HDPE:0.941~0.959 g/cm3 MDPE:0.926~0.941 g/cm3 (PEX) Melt flow index HDPE、MDPE≥0.1 g/10min(190,2.16kg) Tensile strength HDPE≥21MPa;MDPE≥14MPa Enlongation ≥400% Vicat soft point Vicat soft point≥105℃ Cross-linking degree ≥65% ESCR ≥165h Color masterbatch Moisture content ≤0.15% Appearance Uniform granual Volatile content ≤0.5% catalyst Density ≥0.93 g/cm3 Melt flow index ≥0.9 g/10min(190℃,5.00kg) Volatile content ≤0.35% Adhesive resin Appearance Uniform granual Density ≥0.926 g/cm3; Melt flow index 2.0~6.0 g/10min(190℃,2.16kg) Vicat soft point Vicat soft point≥105℃ T peeling strength ≥70N/25mm Aluminum Surface quality Water brush test≥class Tensile strength 105MPa~125MPa Appearance Without oil on surface Hardness(HV) 28~33 T peeling strength Minimum value≥60N/25mm Nominal size(D x e) 14×2.0 16×2.0 18×2.0 20×2.0 25×2.5 32×3.0 40x4.0 50x4.5 63x6.0 75x7.5 Outside diameter (mm) 14 16 18 20 25 32 40 50 63 75 Tolerance of Outer diameter (mm) Min 14.00 16.00 18.00 20.00 25.00 32.00 40.00 50.00 60.60 70.70 Max 14.20 16.20 18.20 20.20 25.20 32.20 40.40 50.50 63.00 75.00 Inside diameter(mm) 10 12 14 16 20 26 32 41 51 60 Tolerance of Inner diameter (mm) Min 9.90 11.90 13.90 15.90 19.90 25.90 30.90 39.40 49.30 57.70 Max 10.20 12.20 14.20 16.20 20.20 26.20 31.90 40.80 50.80 59.70 Pipe thickness (mm) 2 2 2 2 2.5 3 4 4.5 6 7.5 Tolerance of pipe thickness (mm) Min 2.00 2.00 2.00 2.00 2.40 2.90 4.00 4.50 6.00 7.50 Max 2.25 2.25 2.25 2.25 2.70 3.20 4.60 5.20 6.80 8.50 Compression connections:

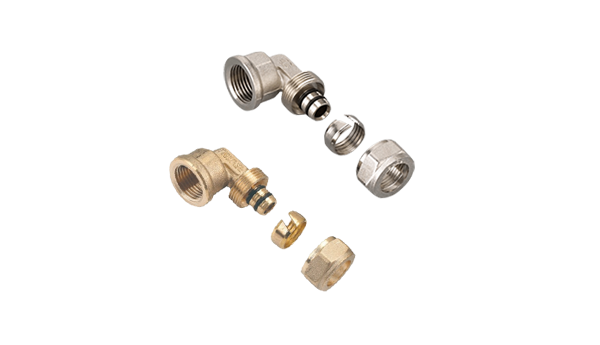

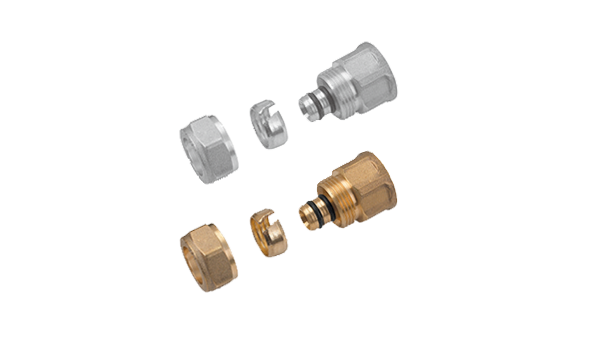

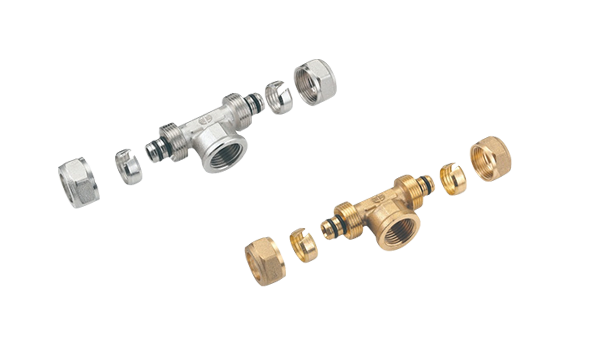

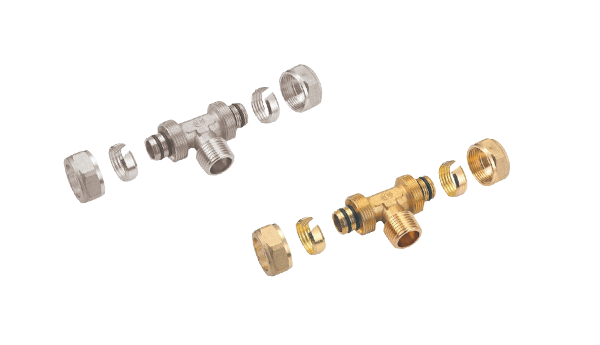

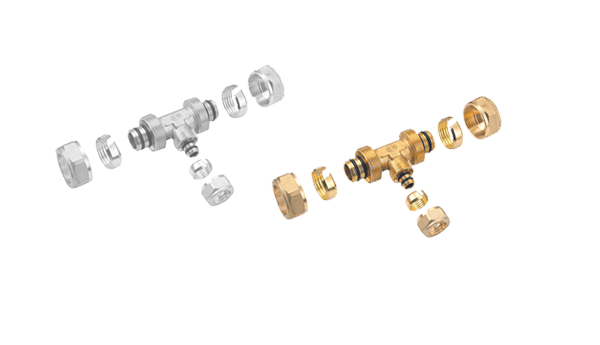

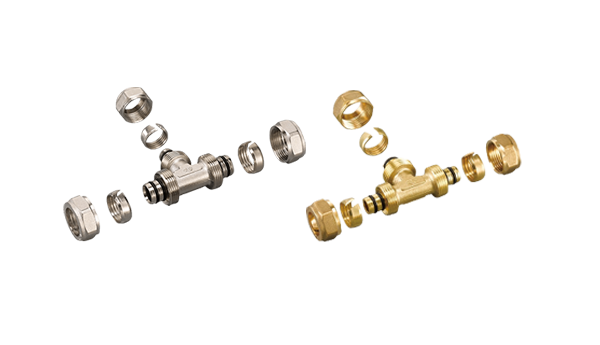

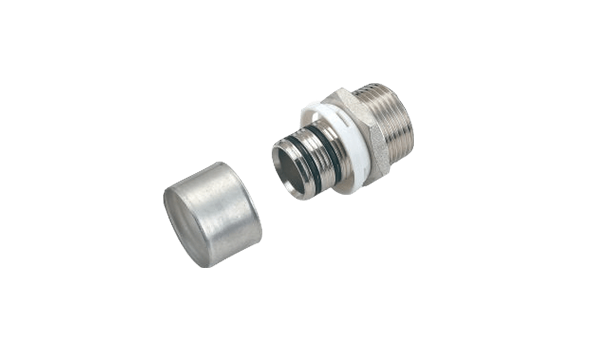

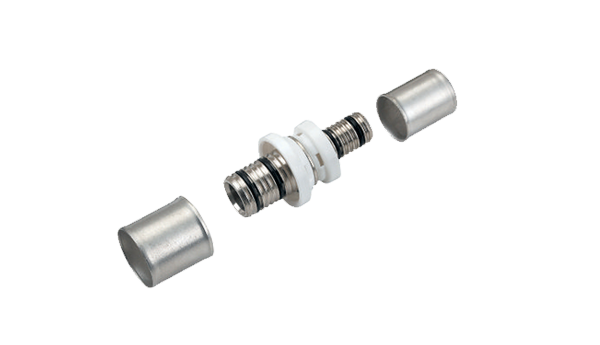

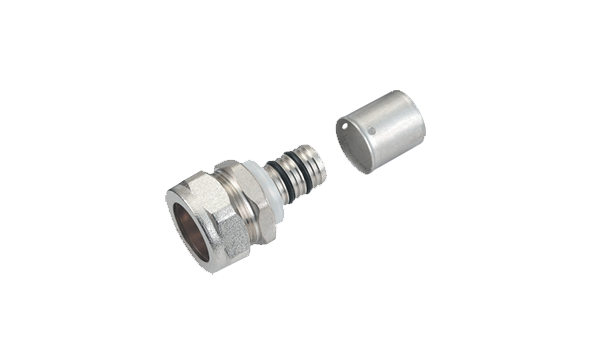

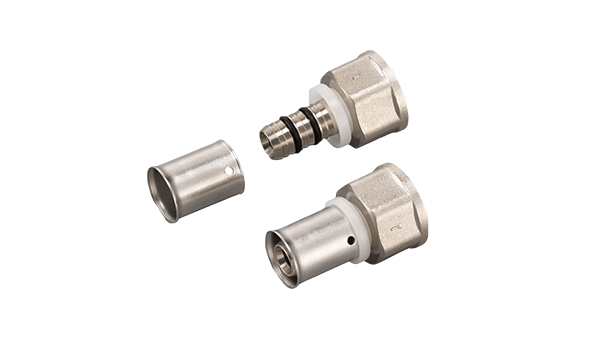

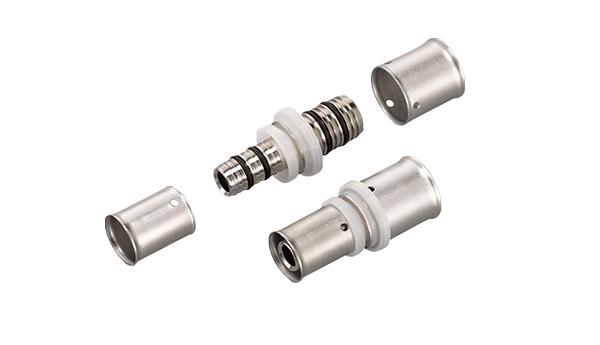

This fitting allows for the connection of multilayer pipes. On the coupling ends, the union with the polyethylene inner tube is sealed by O-rings placed on the removable insert that is introduced into the fitting body and the tube. The connection is tightened by the nut with a wrench.

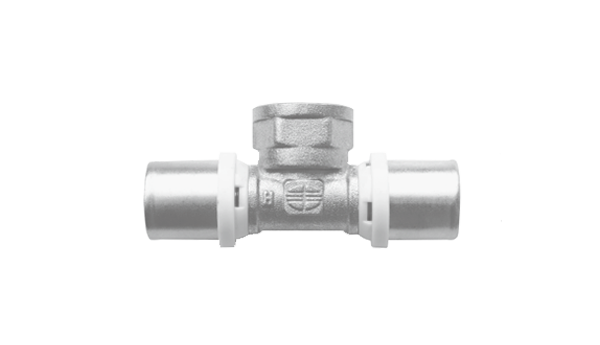

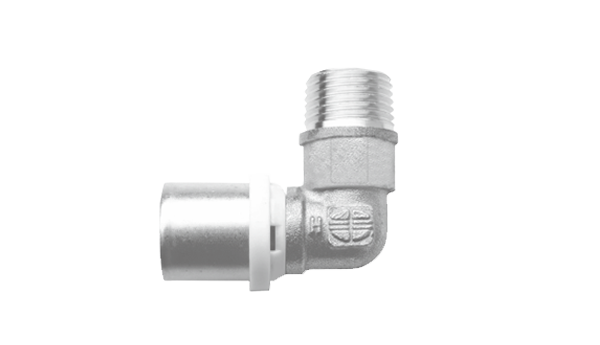

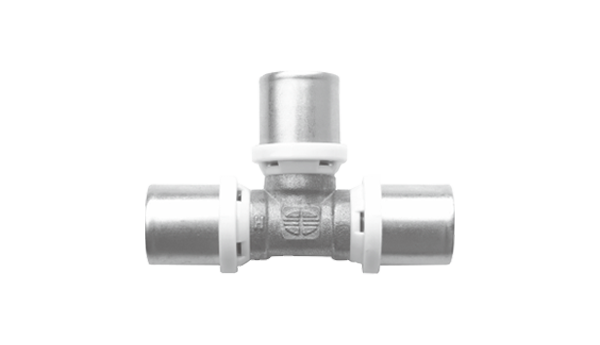

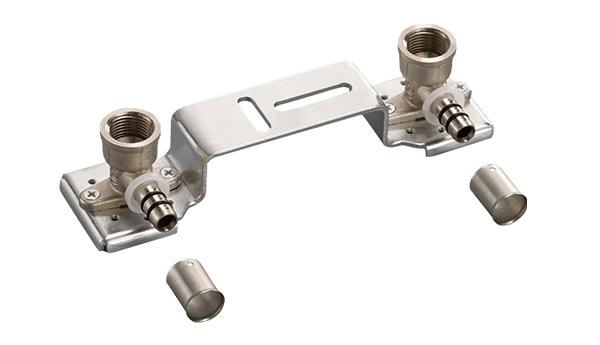

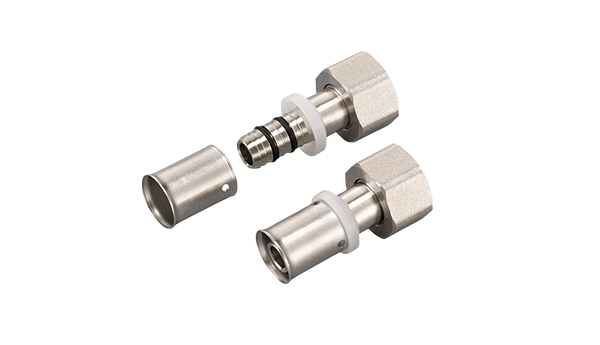

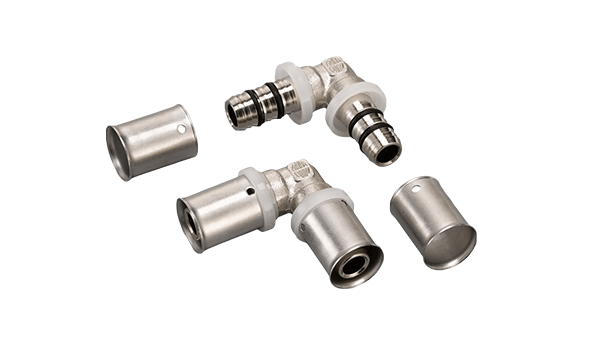

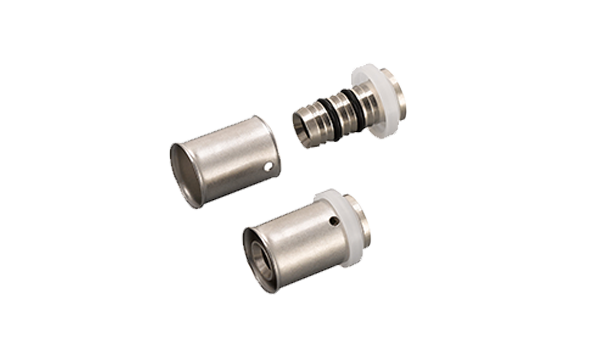

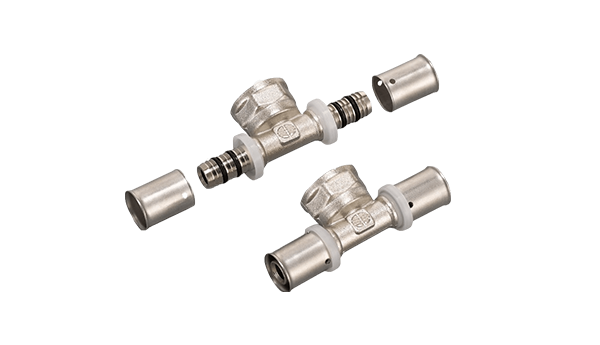

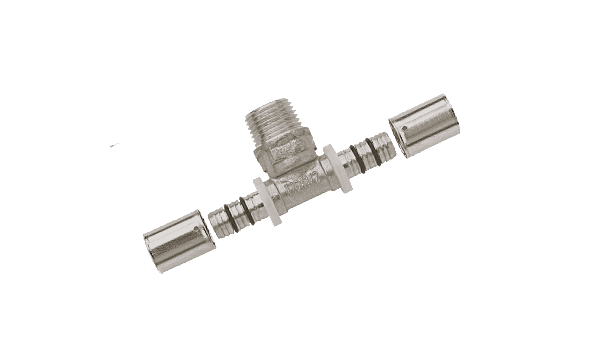

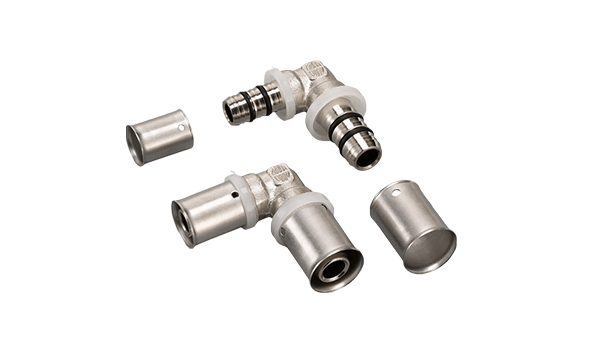

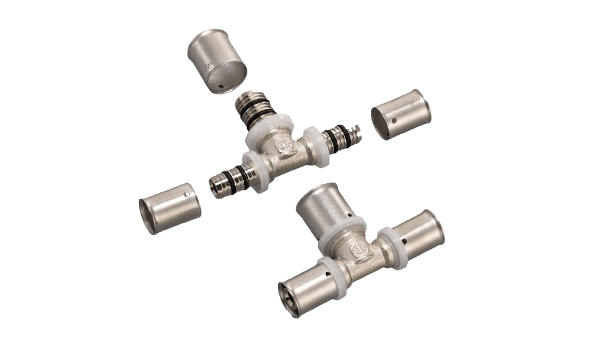

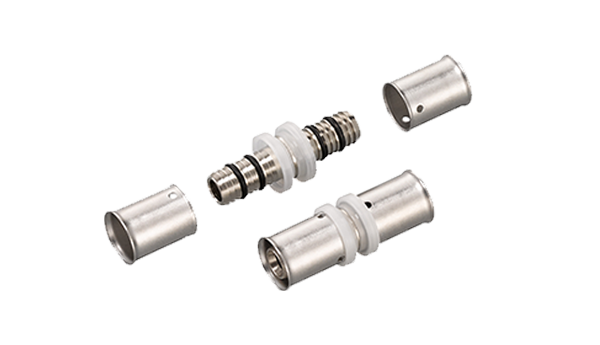

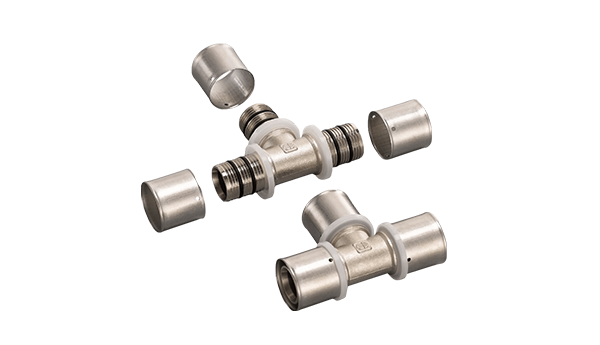

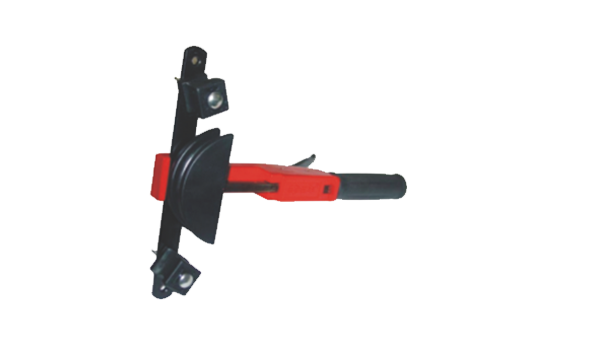

Press connections:

Use special tools, phisically press a connection onto the pipe to make an impermeable connection or seal. RIFENG provide 4 different press fittings.

F5 used with U profile crimper

F9 (leakage indicate) used with TH profile crimper

F17 used with U, TH, H, RFZ profile crimper

F18 (leakage indicate) used with U, TH, H, RFZ profile crimper

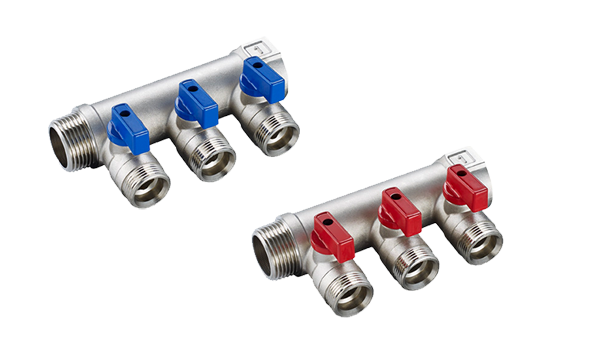

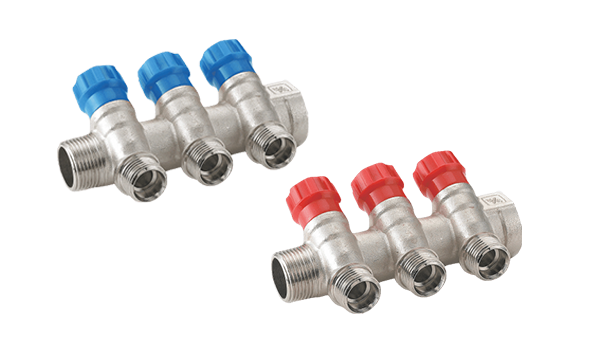

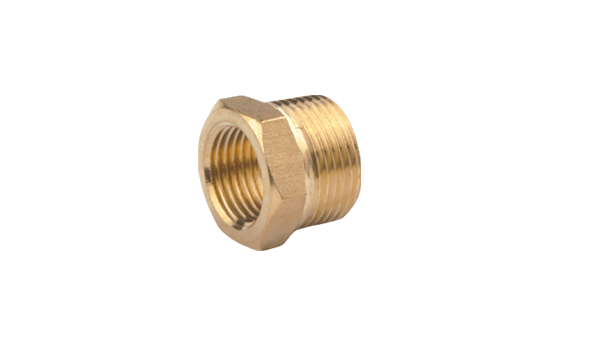

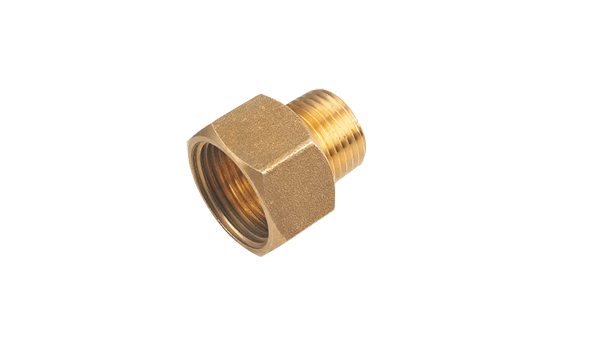

Product Overview

-

-

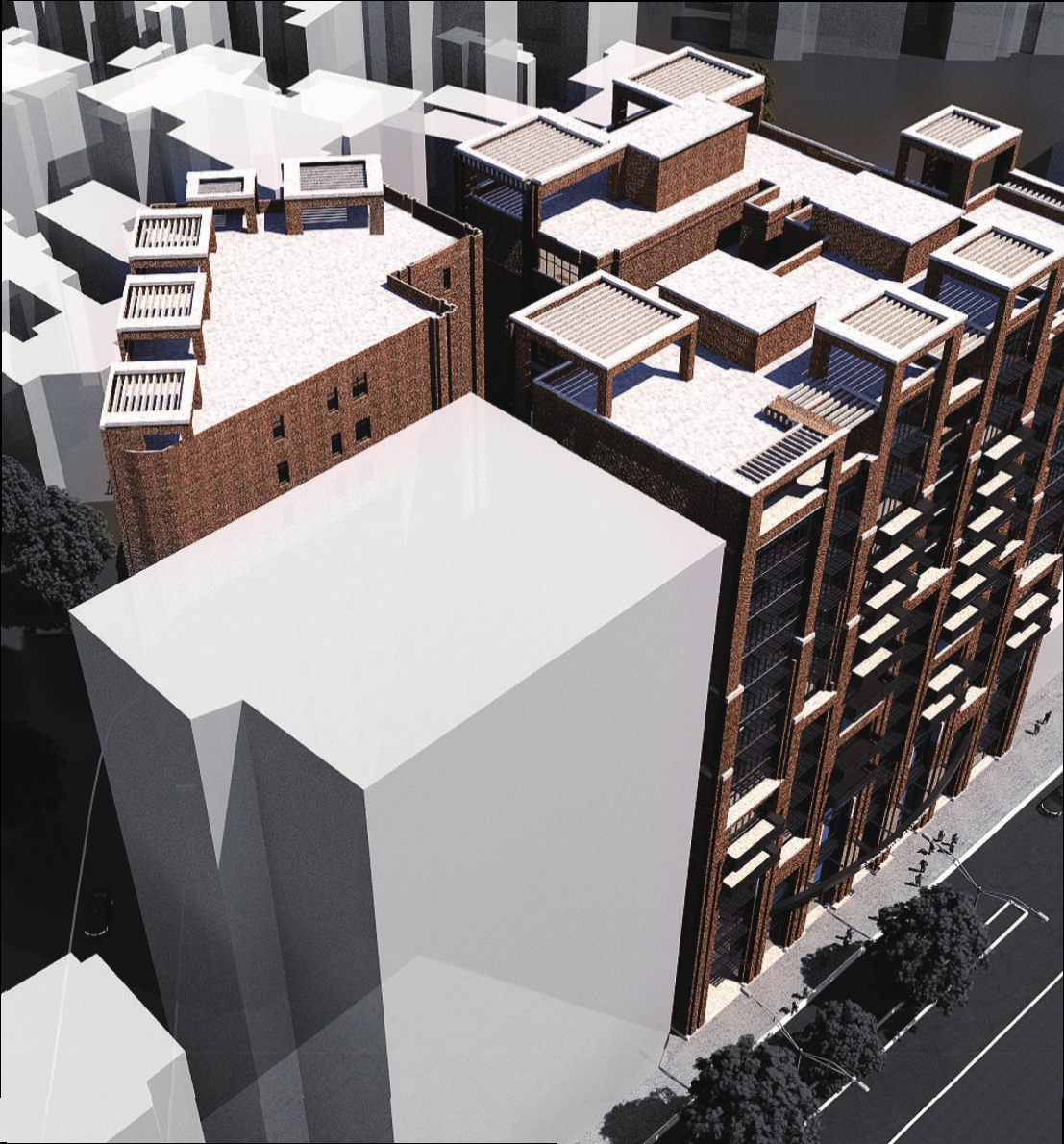

Afroville Diplomatic Apartment 3 Blocks G+13 Building

Developer: Noah Real Estate

Location: Atlas

Year: 2017

Product: Multilayer Plumbing

Elilta mix Use G+20 Building

Developer : Eililta Real Estate

Location: Kera

year: 2019

Product:Multilayer Plumbing

Sikamas mix use 2 block G+11 building

Developer :Sikamas Real Estate

Location : Nefas silk lafto

Year : 2019

Product : Mulitlayer Plumbing